Production

Gudo remains loyal to Switzerland as a production location and will continue to rely on it. At our factory in Lupfig, we use innovative production processes. In addition to the core process of plastic injection molding, we have a variety of other manufacturing and assembly processes.

Our 10 injection molding machines in 1 or 2-component technology, as well as loading robots.

Plastic injection molding

Our state-of-the-art machines work with Clamping forces from 25 to 210 tons and offer the possibility of a loading robot. In addition, we use the advanced 2-component technology, which opens up a wide range of functions and design possibilities.

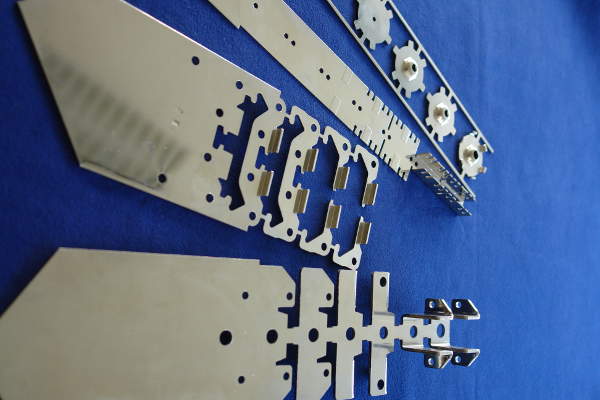

Punching technology

In addition, we have a wide range of stamping tools specially designed for the manufacture of our steel products. We work with external service providers to carry out the stamping. This enables us to ensure that our customers receive high-quality and precisely stamped parts.

All stamping work is outsourced to our partner on our tools.

Various plastic parts are processed with our ultrasonic welding machine.

Further production steps

In addition to our existing services, we can also offer you additional production steps that will meet your requirements even better. These include for example professional riveting or efficient ultrasonic welding, with which we can make your products even more specific and versatile.